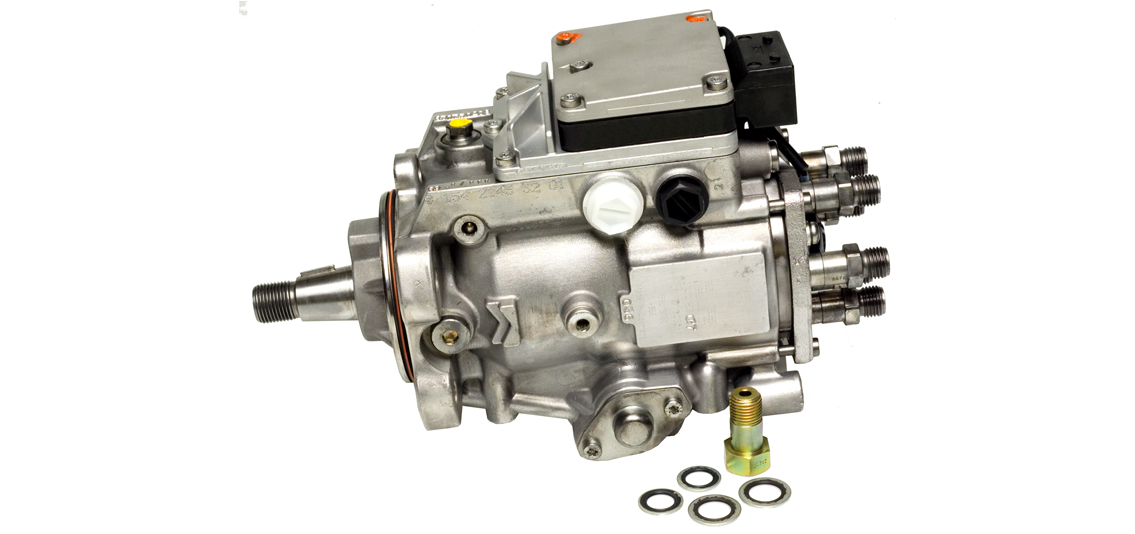

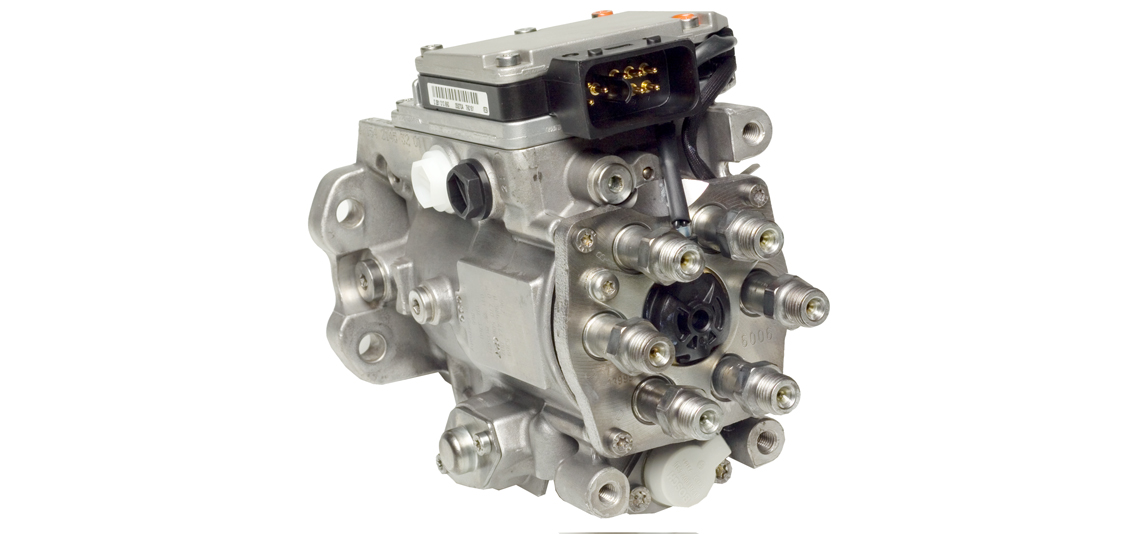

5.9L Fuel Injection Pump (2002-98) - Standard Output

BEFORE YOU INSTALL

Test fuel quality and check the fuel filter for contamination

Verify proper fuel volume output from the lift pump.Install new lift pump if required

Make sure the key is positioned at the 12:00 position prior to removing the IP

Use the new key that comes with the new pump. They are specifically calibrated to work together

After removal, attempt to rotate the pump shaft on the core by hand. The shaft should rotate easily with little pressure. If there is resistance, or a gritty hesitation, this is a good sign the core is contaminated. Flushing the fuel system and use of fresh fuel is always recommended prior to use of the new pump

Any form of modification or tampering voids the warranty of the pump

Related Parts

Fuel Injector - Diesel - New

Diesel Valve Cover Gasket

Features & Benefits

-

Remanufactured at our IATF 16949, ISO 9001, and ISO 14001 certified facility to ensure performance and reliability

-

Completely disassembled and cleaned using three separate methods to eliminate all foreign contaminants

-

All component parts are pre-qualified during disassembly for reclaiming or replacement as needed to maximize performance

-

Dynamically calibrated to OE performance criteria using state-of-the-art electronic testing, which validates flow and checks for leaks to ensure product reliability